Titanium Casting

Titanium Casting

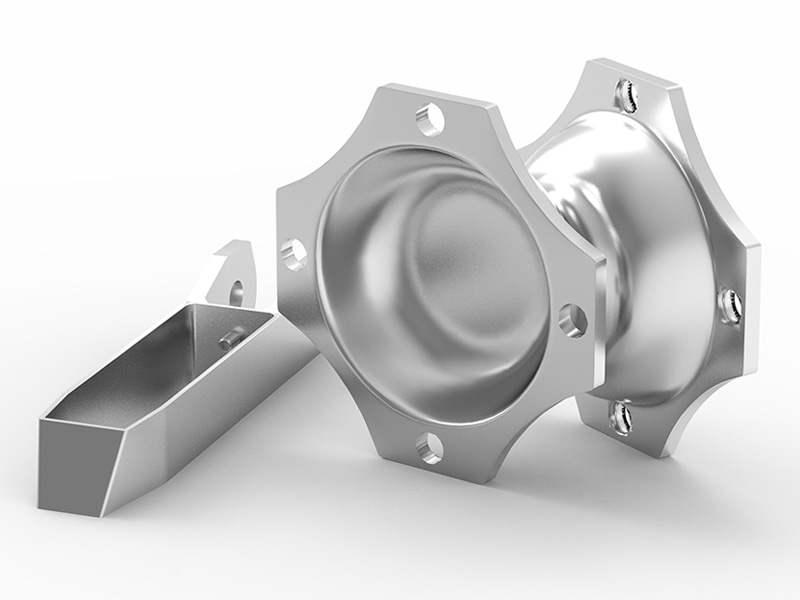

Based on the material research expertise, Nippon Titanium has developed the most advanced titanium casting technologies. Nippon Titanium has been supplying titanium casting parts for international aerospace companies since 2002. We are well capable of casting titanium castings such as titanium aerospace parts, titanium parts for turbochargers, titanium musical instruments, titanium motorcycle equipment, titanium bicycle parts, titanium parts for the oil and gas industries and etc. Our certified welders can repair any surface or sub-surface defects. The welding method used is GTAW with pure argon as protective gas. Welding procedures are qualified to American ASME IX and European PED EN-15614/EN9606.

| Nippon Titanium also specializing in the production of titanium and titanium alloys casting products: | |||||||||||

| Production method: | |||||||||||

| Machined graphite mold titanium casting — This method can simplify molding and effectively control metallurgical quality. Thicker and larger size castings can be precisely made by this method. Ceramic mold titanium investment casting — This method produces more precise castings, with details such as logos being clearly cast. Large sized and complex shape parts can be well cast using this method. | |||||||||||

| Equipment: | |||||||||||

| wax injection machine, desiccant room, dewax machine, vacuum meltower, sinter kiln and Ultrasonic Inspection Machine etc. | |||||||||||

| Casting Size: min 15 x 10 x 10mm, max 2000mm | |||||||||||

| Standard: ASTM B367, JIS H5202 | |||||||||||

| weight: 0-1500KG |